| Features | Endurable and Long Lasting |

| Material | C11000 copper foil, copper content ≥ 99.95% |

| Electrical conductivity resistivity | ≤0.0012Ω/m |

| Current capacity per unit area | 4A |

| pressure drop | 3MV |

| tensile strength | 240MPa |

| twisting strength | 150MPa |

| applications | commonly used as the flexible expansion joints for connecting the bus bars |

| Section area | 10-500sqmm |

| Packaging Details | standard thick carton |

Brief introduction about Tin-, Nickel-, and Silver-Plating copper laminated flexible jumper

Tin, Nickel, and Silver-Plating copper laminated flexible jumper consists of C 11000 copper foils, the both ends of which are press-welded together. It can be tinned coating or silver plating. The length of the contact surface can be designed according to the installation requirements.

They have a constant cross-section over the whole length. Bus bars and laminated connectors with the same cross-section can be loaded with the same current.

A part of laminated connectors are utilized as flexible expansion connectors in order to connect bus bars of switch gears, transformers, generators, etc. Thanks to their elasticity, thermal expansion of bus bars is being compensated.

Most of the parts are being used as expansion connectors to prevent damages by vibration caused by switch gear operations.

Another part is utilized as flexible components inside parts of machines (Like welding machines or switch gears). These kinds of connectors have to realize movement inside machines and switch gears.

To manufacture suitable connectors for the variable applications we have different method of production. So we are able to manufacture connectors in Tin-, Nickel-, and Silver-Plating Copper Laminated Flexible Jumpers.

Standard design has no drilling requirements, you can drill holes on the contact surface according to the drawings.

Insulation material: standard design without insulation material, it can use PVC insulation sleeve heat shrink fixed.

The production process of Tin-, Nickel-, and Silver-Plating copper laminated flexible jumper

The Tin, Nickel, and Silver-Plating copper laminated flexible jumper is formed by two technologies. The first is to press the 0.05mm – 0.5mm thick copper foil laminate together partly, then adopt macromolecule diffusion welding technology. Finally, it is formed by argon welding with high current heating.

The second is to press 0.05mm – 0.5mm thick copper foil together, using silver based brazing material and flat copper block butt welding forming.

Each copper strip of the Tin-, Nickel-, and Silver-Plating copper laminated flexible jumper is cut by CNC punching and cutting machine tools.

This can ensure that the difference between each piece of copper strip is balanced, the accuracy can reach 0.0001mm, and there is no extrusion between each piece due to uneven feeding, fully ensure that the expansion of soft connection is not limited.

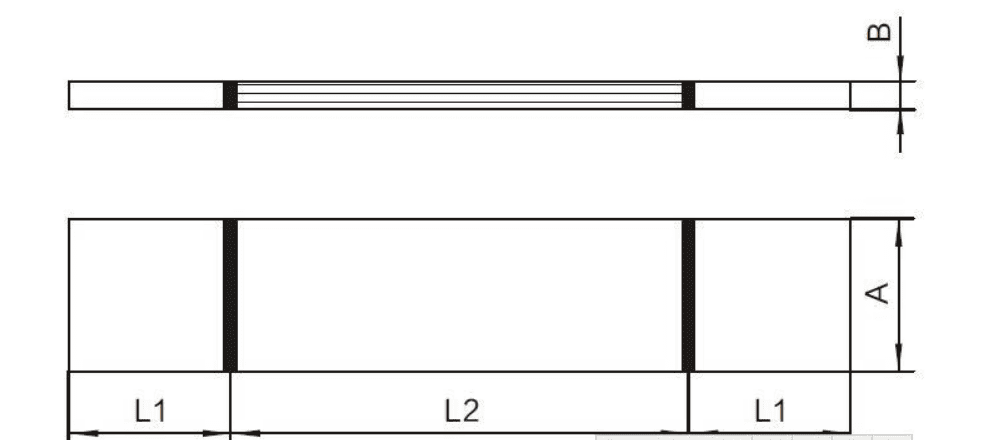

The drawing of Tin-, Nickel-, and Silver-Plating copper laminated flexible jumper

Most of the Tin-, Nickel-, and Silver-Plating copper laminated flexible jumpers are customized according to the drawing.

| Catalog No. | Main dimensions(mm) | |||

| A | L1 | L2 | B | |

| MST – 4×40 | 40 | 60 | 170 | 4 |

| MST – 5×50 | 50 | 70 | 170 | 5 |

| MST – 6×60 | 60 | 80 | 190 | 6 |

| MST – 6.3×63 | 63 | 80 | 190 | 6.3 |

| MST – 6×80 | 80 | 90 | 190 | 6 |

| MST – 8×80 | 80 | 90 | 190 | 8 |

| MST – 10×80 | 80 | 90 | 190 | 10 |

| MST – 8×100 | 100 | 115 | 220 | 8 |

| MST – 10×100 | 100 | 115 | 220 | 10 |

| MST – 10×120 | 120 | 140 | 220 | 10 |

| MST – 10×125 | 125 | 140 | 220 | 10 |

| MST – 12×120 | 120 | 140 | 220 | 12 |

| MST – 12×125 | 125 | 140 | 220 | 12 |

| MST – 12.5×125 | 125 | 140 | 220 | 12.5 |

The application of Tin-, Nickel-, and Silver-Plating copper laminated flexible jumper

The Tin-, Nickel-, and Silver-Plating copper laminated flexible jumper is suitable for the flexible connected wires of electrical equipment, electrical switch, electrical furnace, battery, etc. Also can be as shielding sleeve for wire harness etc.

Copper laminated flexible jumpers have superior mechanical and electrical properties. These connectors are used in power plants, Bus ducts, V.C.B, Electric locomotives, transformers, furnaces, Galvano Engineering and switch gear industries.

Laminated Flexible Copper Connectors are known for their sturdiness, anti- corrosive features, endurable, long lasting, rust proof, easy to use etc.

The usage occasion of Tin-, Nickel-, and Silver-Plating copper laminated flexible jumper