Company Profile

HENAN SUNSHINE HIGH TEMPERATURE MATERIALS CO., LTD was founded in 2017 with a specializing in the research, development, production, and sales of and sales of various types of copper braid flexible wires, flat tinned braided copper wire, copper stranded wires, conductive tapes, copper Laminated flexible connectors, and related copper assemblies. We are committed to providing high quality, reliable copper connects and related copper assembly for global customers.

Company Mission

We firmly believe that innovation, quality and service are the keys to business success. Through sustainable innovation in research and development and excellent product quality, Sunshine offers the best quality copper products solutions to our global customers.

The company sets “Technical Innovation, Pursuit of Perfection” as enterprise goal. We strive to create a professional copper braid flexible connectors customized enterprise in order to satisfy customer’s multiple needs and ensure customer’s competitive advantage in the market.

Products and services

Copper wire business

Our company has advanced high-speed wire drawing machines, high-speed stranding machines, wire bunching machines, and automatic production lines for soft connections. All products are manufactured with high quality copper materials of grade T2 or above and other materials as raw materials.

Braided Copper Flexible wire

We provide all kinds of braided copper flexible wires, with excellent electrical conductivity and high flexibility, can be widely used in electronic equipment internal connection, EMI shielding and other aspects.Tinned copper braid wire

Tinned copper braid wire has excellent anti-corrosion and electrical conductivity, suitable for demanding environments and equipment, such as aerospace and high frequency communication equipment.Flexible copper stranded wires

We produce all kinds of flexible copper stranded wires, with excellent electrical conductivity and mechanical properties, suitable for power transmission, automotive electronics and other fields.Copper Laminated Flexible Connectors

Copper laminated flexible connectors have excellent flexibility and conductive properties, and can be mainly used for high and low voltage electrical appliances, vacuum electrical appliances, high and low voltage switch-gear.

Heating element Business

Sic heating element:

With the characteristics of high temperature resistance, oxidation resistance, fast heating, long life, corrosion resistance, resistance to cold and heat, not easy deformation at high temperature, convenient installation and maintenance.

Mosi2 heating element:

widely used in special industrial fields to provide reliable high temperature heating effect for equipment.

Furnace business

Tubular furnaces, Muffle furnaces, vacuum furnaces, dental furnaces: are used for high temperature heat treatment equipment. It is commonly used in laboratory or industrial fields for technical and quality assurance.

We have an experienced professional R&D team and a professional production team, committed to technological innovation and process improvement. We strictly follow the ISO quality management system to ensure stable and reliable product quality.

Customer & Partners

Henan SUNSHINE high temperature materials CO., LTD has established long-term and stable cooperative relations with many well-known enterprises at home and abroad, our products have been exported to the United States, Southeast Asia, Europe and the Middle East. We aim to win together, with our partners and customers. Sunshine is committed to achieving mutually beneficial outcomes with partners.

Sustainable development and Social responsibility

Sunshine considers its sustainable development and lowering environmental impacts a contribution to the development of the society. We adopt advanced environmental protection production technology, pay attention to employee welfare, participate actively in social welfare undertakings, and fulfill corporate social responsibility.

Henan SUNSHINE high temperature materials Co., Ltd will continue to be committed to technological innovation and high-quality product development and advanced processes development. We aim to be a trusted partner to our clients by providing customers with better and more professional copper products solutions. We look forward to better cooperation with you to develop together and create a bright future.

Innovative R&D

Dedicated to technological innovation and process improvement for superior products

Customized Connectors

Tailored copper braid connectors meet diverse global market needs

Global Service

Committed to delivering reliable copper solutions with excellent customer service worldwide

Unlock solutions

Get the answers you need.

Our Products

We manufacture and supply electric furnace heating rods in various specifications

Copper Laminated Flexible Connectors

Sunshine offers high-performance copper laminated flexible connectors designed for industrial strength and maximum conductivity.

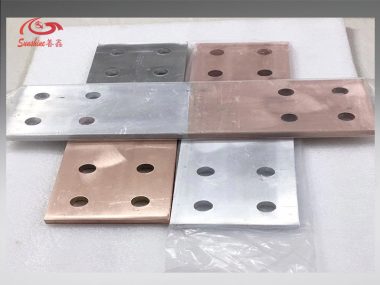

Copper aluminium laminated flexible connectors

Copper aluminium laminated flexible connectors, combining copper and aluminium, designed for high conductivity and flexibility, for optimal performance in power transmission and industrial systems.

Tinned or Nickel Plated Battery Connection Copper busbar

Sunshine produces and supplies high-performance tinned or nickel plated battery connection copper Busbars, ensuring excellent conductivity and durability.Ideal for electrical systems, EVs, and power storage solutions.

Flexible copper stranded wire

Sunshine offers premium quality flexible copper stranded wire In a variety of styles and sizes, designed for durability and performance. Ideal for electrical, industrial, and commercial applications. Get a free quote today!

Flexible copper stranded conductor

The flexible copper stranded conductor as soft connection wire is commonly used in railway overhead contact system projects are TJR-95mm2 and TJR-120mm2.

No-Plating Flexible Copper Foil Laminated Connector

No plating flexible copper foil laminated connector is usually stacked with 0.5mm aluminum foil to form the same section as the busbar, and the two ends are welded to the terminal board.